Quote:

Originally Posted by 94cobra69ss396

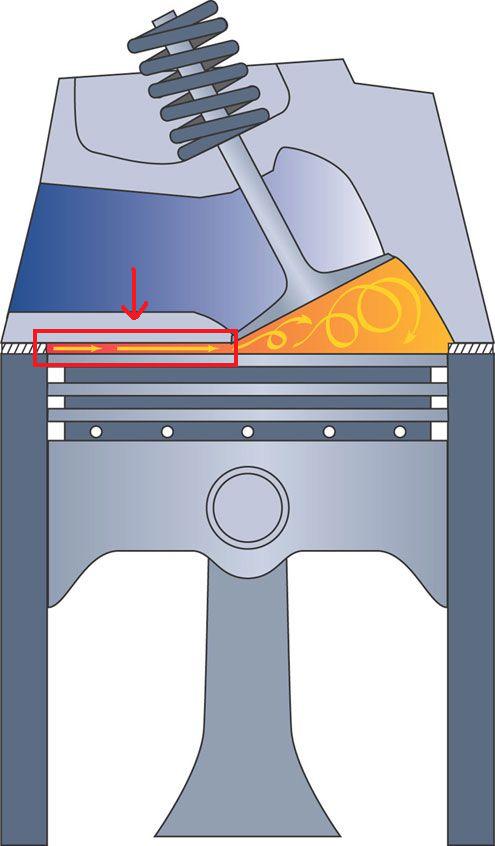

Guys, here's a picture of the quench area that I outlined and have an arrow pointing to. It is where the flat area of the piston meets with the flat area of the head. It can only be changed by using a thicker/thinner HG or by resurfacing the block so that the piston is not as far down in the hole.

I'm just starting to assemble the 355 for our Camaro and need to order bearings and head gaskets so I measured to see how far down the piston is. On our new block the piston is .029 down so I'm going to go with the thinnest gasket I can find to try and get the quench as close to .050 as possible. We are using a forged piston with a long skirt and a tight piston to wall clearance so we could go tighter than .050. |

Good illustration. I use a .032 copper head gasket.